Thermic Oil Supplier in Ahmedabad

Heat transfer oil is a highly refined and stable paraffinic oil designed to be used as a heat transfer medium and quenching oil. In many industrial applications heating is provided indirectly by circulating hot oil through a heat exchanger, thus reducing hot spots and increasing the safety of the heating process. Heat transfer fluids and thermal oils vary in terms of chemical composition. Synthetic products include ester and diester compounds, polyglycol and water-glycol fluids, and silicone-based greases and oils.

Heat Transfer Oil is a mineral oil type used in indirect or secondary heating systems and are manufactured from selected refined paraffinic oils to give excellent resistance to thermal cracking and chemical oxidation, non-corrosive, non-toxic, have low odour level and have no detrimental effect on selected seals.

Many applications in the heat processing industry are well suited to the use of heat transfer fluids to help regulate fluid temperature and provide a controlled environment for chemical reactions. Therminol fluids can be used in both medium-density fiberboard (MDF) and desalination applications.

Most heat transfer fluids and thermal oils are used in circulating process heaters, chillers, or coolers between a heat source and heat sink.

ADVANTAGE HEAT TRANSFER OILS

- Impart highly efficient heat conduction and excellent thermal and oxidation stability properties along with viscosities to maximize liquid-phase startup temperature transitions based on their design.

- One of the greatest benefits of modern heat exchangers is that they do not rely on additional equipment, such as an air conditioning or air compressing unit, to operate. Therefore, they use significantly less energy and produce little or no pollution compared to more conventional cooling methods.

Burner Riello & Benton and Madas GasTrainAnd It's spares. Manufacturer in Ahmedabad

- A gas train is designed to allow for the safe flow of propane or natural gas to your burner. These systems have become more complex over the years as equipment has increased in size and safety has become more of a priority.

- The Riello Burner Selector is an industry first tool that can select the burners that are matched to your boiler requirement. Simply enter your boiler details and the selection will be made for you. Riello is a market leader in combustion technology. For a variety of industries, it has developed an extensive range of safe and sustainable burners, powered by blends of hydrogen or biofuels and with ultra-low nox emissions.

- As indicated above, industrial combustion burners are used to facilitate controlled combustion. By combining and then igniting fuel and air/gas, they provide heat that helps achieve and maintain specific temperatures within the combustion chamber, depending on the levels required for the particular process.

- the burners burning the fuel controlled and transferring the heat homogeneously to the correct channel is done with a combustion chamber. The heat energy produced by the flame is transferred to the place where the energy is required by means of a combustion chamber.

GAS TRAINS

- DK INDUSTRIES offers Gas Trains in Standard and Custom Configuration and Construction.

- Since, The Gas Trains is the essential Part of Gas Burner Safety, DK INDUSTRIES Gas Trains are Manufacture on line of Boiler Safety Regulations. Pre-Piped and Pre-Tested Gas Trains are tremendous Time and Effort savers and are made to be as easy as Plug & Play.

- Gas Trains available for almost all Gaseous Fuels like LPG, Natural Gas, Propane, Biogas and Clean Producer / BF Gas.

- All Gas Trains are tested for Leakages, Flows and Components requiring setting are accurately set to the Set points.

- A Prewired Junction Box is available as option, which facilitates the Wiring of all Electrical Devices on Gas Train at a Single Terminal Strip. Various configurations available as per Customer and Combustion System Requirement, including Flowmeters and Control Valves.

- DK ENGINEERS has vast experience as FD & ID Fan manufacturer in ahmedabad . Our fans are widely used by manufacturers of Boiler, Furnaces, Dust Collection and Ovens with their equipments. We also supply to the end users and offer our consultancy in selection of appropriate ID Fans and FD Fans. Special Care is taken in manufacturing of the impeller (rotating part). All the impellers are statically and dynamically balanced on machine and per IS Grade. Balancing and fan performance certificate is provided along with the blower. DK ENGINEERS make Induced Draft Fan and Forced Draft Fan are designed to runs at high efficiency thereby giving considerable power savings to our customer.

- FD Fan pushes the air into the system creating positive pressure. The system may be furnace/ boiler/ dust collector etc. In furnace & boilers FD Fan sucks the fresh air from atmosphere and supplies it to the burner for combustion. FD Fans are generally direct driven fans. ID Fan pulls the air out of system creating negative pressure. The hot flue gases such from the furnace/ boiler are sucked by ID Fan and thrown into atmosphere (via chimney). ID Fans for high temperature flue gases are belt driven fans.

- Centrifugal Air Blowers based on its application use are called ID Fans or FD Fans.

- Appropriate MOC and thickness of FD Fans & ID Fan impeller is chosen depending on temperature and dust content in air. For high dust load wear pads are provided on id fan impeller blades.

ID\FD FAN, IMPELLERS

DK ENGINEERS has vast experience as FD & ID Fan manufacturer in ahmedabad . Our fans are widely used by manufacturers of Boiler, Furnaces, Dust Collection and Ovens with their equipments. We also supply to the end users and offer our consultancy in selection of appropriate ID Fans and FD Fans. Special Care is taken in manufacturing of the impeller (rotating part). All the impellers are statically and dynamically balanced on machine and per IS Grade. Balancing and fan performance certificate is provided along with the blower. DK ENGINEERS make Induced Draft Fan and Forced Draft Fan are designed to runs at high efficiency thereby giving considerable power savings to our customer.

FD Fan pushes the air into the system creating positive pressure. The system may be furnace/ boiler/ dust collector etc. In furnace & boilers FD Fan sucks the fresh air from atmosphere and supplies it to the burner for combustion. FD Fans are generally direct driven fans. ID Fan pulls the air out of system creating negative pressure. The hot flue gases such from the furnace/ boiler are sucked by ID Fan and thrown into atmosphere (via chimney). ID Fans for high temperature flue gases are belt driven fans.

Centrifugal Air Blowers based on its application use are called ID Fans or FD Fans.

Appropriate MOC and thickness of FD Fans & ID Fan impeller is chosen depending on temperature and dust content in air. For high dust load wear pads are provided on id fan impeller blades.

Features of “DK ENGINEERS” ID Fans & FD Fans

- Less Power Consumption

- High Impeller Life

- Less Maintenance

- Low noise

- High Bearing Life

- Good after sales service

TYPES OF IMPELLERS

- Open impellers. An open impeller has a hub with attached vanes and is mounted on a shaft.

- Semi-closed impellers. A semi-closed impeller has an additional back wall, giving it more strength.

- Closed or shrouded impellers.

- Screw impellers.

- An induced draught fan (ID fan) is provided to maintain a negative pressure in the furnace by sucking the products of combustion from it with a slight positive pressure at the discharge end vis-à-vis the bottom of the chimney/stack.

KSB& MAS make Oil circulation Pump and It's Spares.

KSBstands for Johannes Klein, who along with Friedrich Schanzlin and Jakob Becker founded the company. It is the fourth largest player in the Indian industrial pumps and valves business. KSB yields solutions for transportation and distribution of water, waste water and industrial fluids.

KSB can dissolve silicate minerals and release K through the production of organic and inorganic acids, acidolysis, polysaccharides, complexolysis, chelating, and exchange reactions. Hence, the production and management of biological fertilizers containing KSB can be an effective alternative to chemical fertilizers.

The oil pump is an internal combustion engine part that circulates engine oil under pressure to the rotating bearings, the sliding pistons and the camshaft of the engine. This lubricates the bearings, allows the use of higher-capacity fluid bearings and also assists in cooling the engine.

Dk engineers are manufacturer and supplier of oil circulation pump and it’s spares.

Motor Pump with base Frame suppliers in Gujarat

Frame-mounted pumps are mounted next to a motor on a common base plate, with the pump shaft and the motor shaft connected by a flexible coupling. The design includes a bearing housing to prolong the life of the bearings and allows for continuous operation with high radial and thrust loads.

These strong and sturdy bases are designed to lift your pump and motor off the floor to keep it drier and to allow better cleaning of the pump and the floor.

Base frames are usually made of profile steel, plates through extrusion, or steel tubes through splicing or castings and profile steel through splicing. Base frames should have strong rigidity to avoid distortion of frames during handling and installation, which may impair pantograph performance.

Rotory Airlock Valve Manufacturer

Rotary airlock valves are also called rotary feeders, rotary valves, or just rotary airlocks. Used in both pressure style and vacuum style pneumatic conveying systems, these valves serve as a “lock” to prevent air loss while simultaneously performing vital material handling functions Airlocks serve a number of purposes that include acting as a sealing device against loss of air while maintaining a flow of bulk materials between components in a pneumatic conveying system, used as a volumetric feeder for metering materials from bins or silos into a conveying system, and as a gravity discharger for Polemic produces the three general types of rotary valves, namely flow-through, blow-through and off-set, each suitable for various applications. Flow-through valve types are also known as drop-through valves. The two ports, inlet and outlet, are vertically aligned and tend to be the same size.

The prime function of a Rotary Valve is to regulate the flow of dust, powder and granular products from one chamber to another whilst maintaining a good airlock In the dust filtration field a good airlock is essential on cyclone and bag filter applications in order that the manufacturers quoted high dust collection efficiencies can be maintained. Airlocks are also important in the pneumatic conveying industry, where product is regulated into a pressure or vacuum conveying line while minimizing air leakage.With DK ENGINEERS there are no double standards, all our standard valves are precision machined for close tolerances and minimal eccentricities.

Due to careful design of the internal components the overall dimensions are very similar to our standard range of valves and we can offer a selection of optional features such as purged shaft seals, scalloped rotor pockets and staggered rotor pockets without the throughput being greatly reduced or the barrier efficiency being affected.

About Rotary Airlock Valve

The material is received from the top in Rotary Airlock Valve. Fills volume between rotor vanes and discharge at the bottom side. The material is discharge without air leakage. It can be mount directly on the bottom flange of the silo of outlet spout.

Rotary Airlock Valve Design:

Rotary Airlock Valve consists of flange mounting type housing, rotor and rotor shaft. The rotor is fitted inside the housing. The rotor rotates in bush bearings. Stuffing box with gland packing is provided both sides to prevent material leakage. The rotor is driven by geared motor and chain sprocket.

Available Options:

Different design and construction of material for vanes and housing are offered for the different application.

After sales service support:

We provide a full range of field service and engineering support. The staff of the company is available to assist the customer with instructions, installation, start-up and maintenance

All the data given is nominal only. It may vary widely from case to case depending upon many factors.

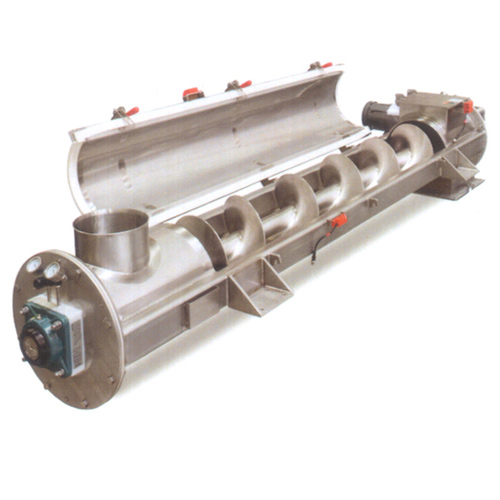

Screw Feeder

- Screw feeders are used for the airlock, pneumatic conveying in high velocity, metered drop-through, feeding, and many point connections. We also have screw feeder designs for specialized injection solutions with screw designs for compaction, airlock & feeding of various materials like fine powders, pellets, coarse powders etc.

- A screw feeder is a vital piece of equipment that is used to deliver granular or fine substances based on your requirements. The capacity of bulk material or feed rate can be controlled to a more accurate degree with the help of a screw feeder.

- As the best screw feeder manufacturer in India, we offer quality products that provide long-lasting service and less maintenance, low cost, low power consumption, and cost-effective and robust technique.

THE BASIC DESIGNS OF A SCREW FEEDER:

The basic design for most screw feeders features a screw conveyor that is fed by another conveyor, and the amount of discharged material is directly proportional to the amount of material introduced at the inlet. The inlet is always flood loaded and is mostly mounted directly to some form of storage device such as a silo, hopper or bin.

To guarantee even and efficient cycling, many factors must be considered when designing a screw feeder. During each revolution, the bulk material is supposed to move from one flight to the next to reach the discharge. If a screw feeder is improperly designed, it can cause problems such as stagnant materials that affect the productivity of the system. to ensure that the flow of the bulky materials is smooth, each flight increases the available volume as the screw must progress towards the discharge.

THE BASIC TYPES OF SCREW FEEDERS:

- Variable or DK ENGINEERS pad Pitch

As it progresses towards the discharge of the screw feeder, the pitch varies from shorter to longer. To create more available volume for the addition of bulk materials from the hopper every pitch grows in length in the inlet section. With a DK ENGINEERSpad pitch, the flight pitch changes in increments. - Tapered Outside Diameter

- The outer diameter of the screw is narrowed from the back end of the inlet opening to the shroud. This helps create additional volume available for the extra bulky materials from the hopper.

- Mass Flow

- DK ENGINEERS developed the mass flow design. It is a combination of variable pitch and tapered inside diameter. A pointed cone is situated in the centre of the pipe. The short pitch flights are mounted on the cone to create additional volume for the additional bulk materials from the hopper. Variable pitch is added tithe screw starting where the cone ends and continuing to the discharge.

- High speed & Low speed screws

- Screw feeder designs can be either high speed or low speed depending on the application and the process. Both of these have certain advantages & disadvantages, and the selection of the type of design methodology depends on the application.

The SLICE-QTC PID Temperature Controller features four independent precision temperature controller channels for DK ENGINEERS heaters for temperature stabilization and control of lasers, semiconductor optical amplifiers, tapered amplifiers, optical cavities, PICs, and non-linear & photonic crystals. The loops can be nested or control four separate systems. With widely adjustable PID corners and gain, it is possible to stabilize the temperature of your plant with sub-millikelvin temperature stability and set point resolution. Download our application note on stabilizing large thermal loads to sub- millikelving stability in the Attachments Tab.

Features like slew rate control and an output trigger allow you to trust your delicate photonic devices such as doubling crystals to the SLICE-QTC. You can set a maximum rate of temperature change and have confidence it won’t be exceeded. Safeguard your laser diodes by automatically shutting down the current if the the temperature goes out of range. Easily tune the PID temperature loop using the loop performance monitoring system.

Our rotary switches are engineered to control many circuits with a single switch. Our portfolio includes a range of rotary switches with multiple actuator styles and shapes, suitable for demanding environmental conditions

Our varied portfolio of sealed and unsealed rotary switches is available in numerous actuator styles and shapes, and various colors. Common BCD and Hexadecimal version available. Our switches are engineered to perform in demanding and harsh environments. Rotary switches are used in industrial and plant equipment, data communication and entertainment systems, and heavy-duty vehicles for commercial, construction, and agriculture

SCR power controllers compensate for mains voltage fluctuations by employing RMS voltage regulation. An SCR's voltage regulation mode adjusts the firing angle (phase angle) or duty cycle (zero cross) of the SCR output to maintain a constant voltage output proportional to the set point. A Temperature Controller is a device that is used to control a heater or other equipment by comparing a sensor signal with a set point and performing calculations according to the deviation between those values

A PID controller is made up of three parts: the proportional part, which drives the output in proportion to the instantaneous error; the integral part, which drives the output in proportion to the accumulated error; and the derivative part, which drives the output in proportion to the instantaneous rate of change. here are two main configurations of rotary switches: those with a single pole and those with multiple poles. Single-pole rotary switches are used to control a single circuit, while multiple-pole rotary switches can control two or more circuits.

Features and Advantages

- 1. High –efficient & energy saving operation

DK ENGINEERS low voltage variable frequency drive with High –efficient & energy saving operation and new PWM dead zone compensation technology, motor consumption can be effectively reduced, achieving maximum power saving rate. - 2. Fast dynamic response

DK ENGINEERS VFD advanced motor mode control can also quickly response to load change without PG card. - 3. Smooth tracking start

At any time, moth start can be perfectly achieved without impacting the rotating motor. - 4. Powerful grid adaptability

Automatic voltage adjustment function: when the grid voltage changes, the output voltage can be automatically kept constant. In the case loss of electricity, unique non-block our function can keep VFD running. - 5. Stable operation with low frequency and high torque.

Dynamic calculation of IGBT internal temperature ensures that the IGBT module operates with the temperature limits, improving reliability of the module. - 6.Positive-reverse switch

When positive-reserve motor switch to the zero-speed, the phase of current has no change or oscillation, and speed has no ripple. - 7. Rapid acceleration

full load acceleration with fast torque response and low speed overshoot. - 8. IGBT temperature protection curve

Dynamic calculation of IGBT internal temperature ensures that the IGBT module operates within the temperature limits, improving reliability of the module. - 9. Reliable design for heat dissipation

The temperature distribution and wind direction of VFD have strict simulation calculation, improving environmental adaptability.

Refractory Materials Like Fire creat super, Mortar, WhiteK,Fire clay, Insulation Bricks, Fire Bricks etc

Refractory materials that keep their chemical and physical of high importance for metallurgical and other industrial processes. They consist of alumina, magnesia, silica, lime, and other metal oxides. Maddox Fire Clay is used to make mortar to set block, brick and stone. The clay can be mixed with sand (not included) and cement (not included) to produce mortar and stucco. Also may be used as a component of refractory mortar. This product is to be mixed with other raw materials, not to be used alone. The Insulating Fire Brick (IFB) is a type of soft brick made of refractory ceramic material, a blend of alumina and silica, that can withstand extremely high temperature applications and has a low thermal conductivity. This IFB is an excellent insulator and reflects heat well.

- We manufacture high quality Fire Bricks. Each lot is manufactured using high quality tested raw materials, fired efficiently under strict quality control and proven production technology to maintain consistency. Fire Bricks manufacturing has a stringent IQC and OQC procedure ensuring each batch is conforming to the specification.

- DK ENGINEERS is an ideal manufacturer and supplier of Alumina based refractory mortars in ahmedabad , heat resistant refractory mortar, fireclay mortar for bonding high alumina bricks and fireclay bricks. Our High alumina mortar is manufactured using high standard of fireclay materials, which greatly add to its strength and performance. Our High alumina refractory mortar is the best choice for high temperature fireplace, ovens, kilns, furnaces, and chimney construction. Mortars are joining materials for laying refractory bricks. DK ENGINEERS produces a wide range of fireclay and high alumina mortars. Refractory mortars are used as jointing materials for various insulation and high alumina bricks

- Some of the mortars are supplied as a two component system, where liquid binder is separately provided with powder material. Where water is used as liquid component, the amount of water used should be such that it results in trowel ling consistency.

- Fire clay brick, fire proof clay bricks, or refractory clay bricks are a block of refractory ceramic material used in lining furnaces, kilns, fireboxes, and fireplaces. Such a brick is manufactured by DK ENGINEERS primarily to withstand high temperature, but will also usually have a low thermal conductivity for greater energy efficiency. Our company manufactures and supplies these refractory fire bricks for Steel, Glass, furnaces and various other industries, where fire is needed for survival. Ordinary bricks will not be able to survive in such a temperature.

- DK ENGINEERS is a reputed and known manufacturer and supplier of high quality fire bricks. The fire clay brick are widely available in shapes & sizes, and they can be customized in many other shapes & sizes as per customer/site requirement.

Fire Bricks

Refractory Mortars

Insulation materials Like Glass wool, Fiber rope, Fiber strip, Aluminum sheet etc. suppliers in Gujarat

Glass wool is an insulating material made from glass fibers. These fibers are arranged using a binder into a texture similar to wool. This process traps small pockets of air between the glass, which give the final product its superior thermal insulation properties. It has good flexibility, affordable price and it is easy to install. Features of fiber glass wool are nature products, acoustical absorption, high thermal resistance with low thermal conductivity fire safe materials and environmental friendly materials.

Fiber ropes are Used for sewing canvas and whippings. Spun yarn - tarred three ply hemp used for servings and seizing’s. Marline - tarred two ply hemp used for serving wire rope and seizing’s. These are the natural fiber types. stripping is the act of removing the protective polymer coating around optical fiber in preparation for fusion splicing. The splicing process begins by preparing both fiber ends for fusion, which requires that all protective coating is removed or stripped from the ends of each fiber.

Aluminum sheets have a wide range of applications within the construction and housing industry. Some of the many uses of aluminum include gutters, siding, roofing and cladding. After steel, aluminum is the second most used metal in buildings.

Glass wool Acoustic Panels

Fiberglass ceiling board with white fiberglass tissue Product introduction of the glass wool board DK ENGINEERS glass wool board is a plate product with a fixed strength after hot-setting the centrifugal glass wool. It has excellent thermal insulation performance at DK ENGINEERING

DFGCaluminum strips - double fiber glass covered varnish bonded aluminum strips are used in dry type transformers replacing copper round wires. The aluminum strips of grade are covered with fiber glass (yarn) & varnished with best insulation.

Applications: these DFGC strips are widely used in all type of transformers like stabilizers, ups, inverters, traction motors, lit& ht coils..Even welding machines and rectifiers are now wound with DFGC strips. In order to reduce the cross sectional area of coils. Even polyester film coating + fiber glass covered aluminum strips are now developed for better bdv and inductors & chokes. Hence double fiber glass covered aluminum strips have better efficiency and good results. In wooden reels.

Fire door suppliers in ahmedabad

In the very same order to provide safety against fire, Fire Rated Rolling Shutters are in the store which look and operate in the same manner as traditional single skin rolling shutters. The only difference is the material used and the fixing type.

This Fire Rated Rolling Shutters designed to stay open under normal circumstances, and close automatically in the event of a fire are structured and constructed to prevent the spread of fire to adjoining areas.

For openings that require a two to four hour fire rating we provide fire rolling shutters utilizing advanced technology and according to specifications of European Standards/FM Global/British Standard/CBRI.

Fire rated rolling shutter can be Integrated with Touchless entrance control solutions like Face recognition, Proximity Card and face with Mask/Temperature that effectively reduces the possibility of contact as well as helps the person to comply with the safety norm in high risk areas.

FEATURES

- Fire Rated Rolling Shutters acts as a barrier & prevents the fire spread in case of fire breakout from one area to other.

- The door comes down gradually in case of fire automatically after receiving signal from fusible link

- Exova Warrington UK certified fire rolling shutters conforming BS 476 Part 22

- EN/UL/FM Global certified shutters also available.

- All steel components of the fire rolling shutters are designed and fixed to provide complete sealing.

- Newly designed & tested G type guide specially for fire rolling shutters

- All components of our shutters are made from High Grade Steel.

- All the Fire Rated Rolling Shutters are available in a number of different finishes or can be powder coated in customized colors.

- Electric release and delay timer can be provided as optional accessories to meet specific customer requirements

- The doors can include additional safety and operational devices such as smoke detectors, flashing lights, buzzer or fire alarms

- Shutter integration to BMS system can also be done if required

Ash door suppliers in India

Ash Doors are a door variant of Ash Wall. They act like all other doors, but are much stronger then all others. Ash is an open grained wood with a grain pattern similar to Red Oak, but without the reddish tone. The heartwood of this wood has a gray-brown color while the sapwood tends to be a light creamy color. Ash wood (fraxinus) is strong, dense, lighter in color than oak and smooth to the touch. It takes gluing, stains and polishes well, making it popular for woodworking projects. Less prized than oak and more physically appealing than beechwood, Ash is a great middle-ground for many tasks White Ash Tree (Fraxinusamericana L.) The name ash comes from the word “spear,” which could be a reference to its spear-shaped leaves or the fact that ancient peoples used the tree to make weaponry.

Ash Doors are a door variant of Ash Wall. They act like all other doors, but are much stronger then all others. Ash is an open grained wood with a grain pattern similar to Red Oak, but without the reddish tone. The heartwood of this wood has a gray-brown color while the sapwood tends to be a light creamy color. Ash wood (fraxinus) is strong, dense, lighter in color than oak and smooth to the touch. It takes gluing, stains and polishes well, making it popular for woodworking projects. Less prized than oak and more physically appealing than beechwood, Ash is a great middle-ground for many tasks White Ash Tree (Fraxinusamericana L.) The name ash comes from the word “spear,” which could be a reference to its spear-shaped leaves or the fact that ancient peoples used the tree to make weaponry.

- Firebars are used to support the fuel within the fire from falling into the ashpan when it's burning. There are several firebars in an appliance, usually around 9 of them. Most appliances will hold 2 or more different types of bars with the most common being large end or small end.

- Keeping in mind the precise demands of patrons, we offer a qualitative assortment of Boiler Fire Bar.

- Our offered bar is extensively demanded by our customers to use in boilers for its sturdy construction and high durability. Available in numerous standard sizes and dimensions, our provided fire bar is easy to install and maintain.

- Additionally, our offered fire bar is extensively acclaimed for its high performance and robust body. Our respected patrons can avail this fire bar from us at market leading prices..We have special grade fire bar made for husk, coal and wood. Our fire bar is capable of withstanding high temperatures and is of robust construction. Our slim design fire bar allows the fire bar core temperature to minimum level due to better cooling.

- Our fire bars are made of high quality Cast. We have special grade fire bar made for husk, coal and wood. Our fire bar is capable of withstanding high temperatures and is of robust construction. Our slim design fire bar allows the fire bar core temperature to minimum level due to better cooling. DK ENGINEERS are manufacturer and supplier of fire bar in ahmedabad,Gujarat .

Support Bar

Service bar means an area where alcoholic beverages are stored and prepared for table service delivery to patrons for on-premises consumption. Consumption of alcoholic beverages by patrons or any other person is not permitted at the service bar. The delivered Busbar Supports system range is a sheltered, prudent and low upkeep approach to fathom portable zap prerequisite.

Contingent upon the application there are different choices and accessories that can be uniquely designed for conductor bar framework. Holder braces are utilized for cinching the Bus Bar Supports. These are fabricated with high cast iron and steel. They are basically utilized as holders for linkage of different machine components with fasteners and nuts.

We are Manufacturer, Supplier, Exporter of support bar and our setup is situated in Ahmadabad India. These grate bar are used in the furnace upon which the fuel is burned. These bars are manufacture with various alloy compositions, depends on the fuel used in the boiler. The intermittent gap in the grate bar / fire bars allows the air flow for combustion. Proper selection of the gap is necessary to avoid the fuel from falling down, while burning.

Level Indicators manufacturers and suppliers in ahmedabad

Detect and measure the level of a liquid within a tank with level indicators. Standard technologies used to measure level include floats, pressure or depth sensors, ultrasonic detection, and conductivity level measurement.

Level indicators are devices used in the measurement of level of fluids at various industrial applications. These devices are used to determine the level of liquid in tanks, drums. pressure vessels etc.. There are many level indicators to suit the needs of different applications.

Level Indicator

Providing you the best range of tubular level indicator, float and board level indicator and level indicator with effective & timely delivery.

Float And Board Level Indicator

- Nilkanth Enterprise offer Float Board Type Tank Level gauge (indicator) suitable for large non

- The Indicator is fitted between two end blocks through gland packings. The indicator is mounted parallel to tank so as to form a close loop causing tank liquid to seek its level in the gauge..

- Glass removal for replacement possible w/o dismantling the gauge.

- 100% PTFE bush as packing to ensure positive leak tightness for full vacuum as well as 6 kg/cm service pressure.

- We are providing Air Vent plug at top & drain plug at bottom for taking sample.

- We can also provide inbuilt isolation valve or offset constructed isolation valve on request.

Magnetic Level Indicator

FILPRO make Magnetic Level Indicator provides clear, high clarity indication of liquid level. Typically, Magnetic Level Gauge consists of three major components: Float Chamber, Float and Indicator System. Magnetic Level Indicator is principally designed as an alternative to glass level gauges. We offer Magnetic Level Gauge having top-bottom, top and side mounted construction with two types of indicator system i.e. Capsule and Bi-colour Rollers. Magnetic level indicators are tailor made to various types of construction and sizes.

Working Of Magnetic Level Indicator

Magnetic Level Gauge operates on the principle of magnetic field coupling to provide fluid level information. Float chamber is typically constructed with non-magnetic pipe having process connections that matches to the vessel connections. Float size and weight is determined by the process fluid, pressure, temperature and the specific gravity of the process fluid.

Magnetic level switch suppliers in ahmedabad

Description Magnetic level switches are used for the monitoring and control of liquid levels in vessels. Magnetic level switches are manufactured to customer specification. An overview of types available with minimum lengths of measuring tube is set out on the following pages.

Magnetron float level controls use a simple float and magnetic coupling action. As the float rises or falls with liquid level, it moves a magnetic sleeve into or out of the field of a switch actuating magnet, causing switch operation. Magnetic level gauges use magnetism to link the indicator in a gauge to a float inside of a vessel in order to accurately show the level of fluid within A level switch is a sensor that detects the presence of liquids, powder, or granulated materials at a specific location. (It is also referred to as level sensor) For example, when a tank is supplied with liquid, it overflow.In order to prevent overflows, a level switch is installed near the top of the tank. Level switches fall into two categories, which are point and continuous.

Point level switches include optical, horizontal float, vertical, and ultrasonic. Continuous level switches include submersible, ultrasonic, and capacitive. The level controller uses a displacer connected to the controller to sense the liquid level. The displacer sits in the process fluid inside of the separator. When the liquid level increases and the displacer reaches a high set point, the level controller sends a pneumatic signal to open the control valve.

Magnetic Level Switch- Side Mounted

CRISTAL Magnetic Level Switch (side mounted 1ype) is float-operated working on magnetic repulsion principle. Simple in design and robust in construction together with strict quality control makes the switch a very reliable product.

This can be used for initiating high or low audio-visual signals or automatic level control of liquids in pressurized or open tanks. containers, hot water service, sterilizing equipment and a variety of process control fluid tanks.

OPERATION

The float assembly carries a permanent magnet. With the float movement. this magnet repels another magnet kept inside the switch housing which In tum actuates a micro-switch having snap action of contacts.

MAGNETIC LEVEL SWITCH - TOP MOUNTED

DK ENGINEERS GEM' Level Switch (top mounted 1ype) facilitates any number of pre-determined level controls initiating audio-visual signals with a single unit. It is designed to provide reliable operation in severe industrial applications. The unit consists of a vertical guide pipe (stem) within which are located the sensor switches, magnetic float sliding over the stem according to the level in the tank, switch terminal housing (head) and necessary mounting connection.

The Switch operates on the basis of the float principle with magnetic transmission (permanent magnet-reed switch).

The switch is encapsulated in the stem and it is actuated by a permanent magnet within the float.

PT-100 Sensor (Thermocouple)

Often resistance thermometers are generally called Pt100 sensors, even though in reality they may not be the RTD Pt100 type. Pt refers to that the sensor is made from Platinum (Pt). 100 refers to that at 0°C the sensor has a resistance of 100 ohms (Ω). A resistance thermometer is a type of temperature sensor.

Pt refers to that the sensor is made from Platinum (Pt). 100 refers to that at 0°C the sensor has a resistance of 100 ohms (Ω). A resistance thermometer is a type of temperature sensor.

It consists of an element that uses resistance to measure temperature. As mentioned previously the Pt100 temperature sensor falls into a group of sensors called Resistance Temperature Detectors. The key word is “Resistance” because a Pt100 measures temperature by using a resistance change to denote the temperature value.DK ENGINEERS are suppliers and manufacterers of pt-100 sensor.

Pressure Gauges suppliers in India

These four types of pressure measurements are gauge, sealed, absolute and differential. pressure gauge, instrument for measuring the condition of a fluid (liquid or gas) that is specified by the force that the fluid would exert, when at rest, on a unit area, such as pounds per square inch or newtons per square centimetre. A device that uses the surface area and weight of a liquid column to measure and indicate pressure is known as a manometer.

Most gauges calculate the pressure relative to atmospheric pressure as the zero point. Hence, this form of reading is known as gauge pressure. Pressure gauges are analog as well as digital. Pressure gauges are an essential instrument used by industry to measure the pressure in a system as a quality check measure and to ensure the consistency of products. For reasons of safety, pressure gauges monitor fluids, gases, and steam for leaks or a build up of pressure in a system.

Pressure Guages Types: Variety of models based on sensing elements such as Bourdon, diaphragm, Capsule, etc. are available as well as special gauges such as Absolute Pressure Gauges, Master / Test Gauges, Mud Gauges, Solid front Case, liquid (Glycerin / Silicon filled) gauges, Receiver gauges, hygiene / sanitary gauges, etc. are available.

Diaphragm Seals: Diaphragm Seals are available in various designs such as flush diaphragm seal, Sandwich type “I” section diaphragm seal, Pan cake type diaphragm seal, in-line type diaphragm seal, jacketed type in-line diaphragm seal, extended type diaphragm seal, Capillary type diaphragm seal, etc.

For high temperature applications diaphragm seal are provided with Silicon oil grade DC 200, DC 704, DC 705, DC 710 etc and based on specific request Fluorolube oil, glycerin, halocarbon oil, food grade vegetable oil is also provided.

Range: Pressure Gauges designed from pressure range Vacuum (-) 1 to 3000 kg/cm2 ( higher ranges upon request). The latest IP-68 protection is offered as standard feature for all gauges.

Accessories: Gauge Saver, Snubber (Pulsation Dampener), Cooling Tower, Syphon, Gauge adaptor, Swiveling adaptor, Gauge Cock, Needle Valves, Manifold Valve, flushing ring, pointer puller and fixture kit, etc. are available.

Special Features: Maxima pointer, NACE Compliance, Colour band, dual scale range, liquid filed case, O2 (oxygen cleaning), N2 (Nitrogen cleaning), Ammonia gauges, blow out disc at back, vacuum protection, capillary extension, micrometer pointer and many other features.

Unique design of external zero reset Knob for liquid filled Pressure gauges wherein zero can be adjusted without opening the case and bezel and draining the liquid filling from case. This special feature is developed by GIC and essentially demanded by oil and gas / hydrocarbon industry onshore and offshore.

Diesel Engine manufacturer in Gujarat

- The diesel engine is an intermittent-combustion piston-cylinder device. It operates on either a two-stroke or four-stroke cycle (see figure); however, unlike the spark-ignition gasoline engine, the diesel engine induces only air into the combustion chamber on its intake stroke.

- Each has its pros and cons for home or office energy use.

- Clear Diesel. The most common type of diesel oil is “clear diesel.” This is the fuel you can buy at the gas station pump. ...

- Dyed Diesel. Dyed diesel is specific to agricultural or off-road use. ...

- Diesel Exhaust Fluid.Diesel engines typically operate at elevated intake manifold pressure (e.g., via turbocharging) and are not prone to knocking or pre-ignition as are premixed charge gasoline fueled SI engines. As a result, diesel engines can produce significantly more torque at low engine speeds than naturally aspirated SI engines.

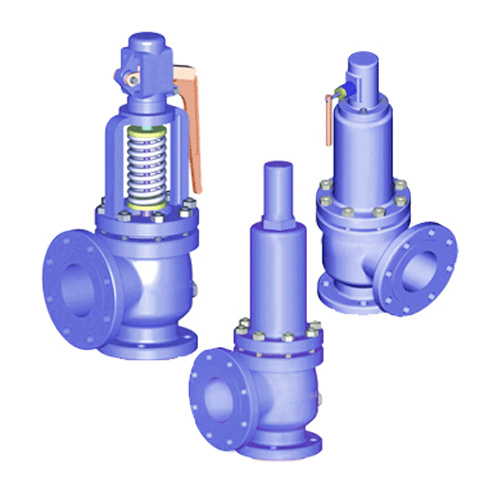

Safty Relief Valve supplier from ahmedabad

- Safety relief valve - A pressure relief valve characterized by rapid opening or pop action, or by opening in proportion to the increase in pressure over the opening pressure, depending on the application, and which may be used either for liquid or compressible fluid. In steam systems, safety valves are typically used for boiler overpressure protection and other applications such as downstream of pressure reducing controls.

- Although their primary role is for safety, safety valves are also used in process operations to prevent product damage due to excess pressure The Importance of Pressure Relief Valves. The pressure relief valve is one of the most important types of safety valves.

- It was designed to control or relieve overpressure levels for optimal functionality in any system, including chemical, petrochemical, power, and oil and gas industries. There are two main types of safety valves. Spring loaded safety valves and pilot operated safety valves.

- Safety Relief Valve represent the most advance technology in value designed for use in intermediate power boiler and organic fluid vaporizer service.

- Built in conformance to section I of the ASME boiler and pressure vessel code, all capacities am certified by the national board of boiler and pressure vessel inspector at 5% over pressure.

- DK engineers Designed by Safety Relief Valve with Full Nozzle & hardened disc to minimize maintenance and increase seat life.

Open bonnet and Close bonnet both design have maximum set pressure 75 bar in Relief Valves

Unlike the gate valve, globe valve can be used for regulating flow or pressures as well as complete shutoff of flow. It may also be used sometime as a pressure relief valve or as a check valve. Compared with a gate valve or ball valve, the globe valve has considerably higher pressure loss in the fully open position. There are three basic globe valve body designs: Tee, Angle, and Wye.

DK ENGINEERS are global and integrated Globe Valves manufacturers in India selling and distributing our supreme range of products at most suitable prices.

Our products range is exported in local and international market as per industry requirements. Precisely engineered and manufactured, our globe valves are taken as quality pieces in manufacturing industry.

Our products are available at most competitive prices having commendable functionality and user friendly nature that makes our valve products highly demanding in market.

Further, being reputed Globe Valves manufacturers in India, we also give custom solutions to our clients as per their usage and industry requirements. You can place either bulk or small order with us; our staff is always ready to help you with cutting edge valve solutions.

WHAT ARE THE FEATURES?

- Sturdy design and robust construction

- Dimensionally accurate and précised

- Custom solutions to complete varied industry demand

- Wonderful performance and better shelf life

Advantages of Globe Valves

Globe valves are easy to operate because they only require a quarter turn to open or close. A Handle or a lever attached to the stem opens or closes the valve This makes them ideal for applications where quick operation is necessary, such as in emergency situations.

Strainers manufacturer in Ahmedabad

An industrial strainer removes noticeable material from fluids, gas, steam, or other vapors. An industrial strainer also known as a pipe strainer, is usually a necessary part of the pipeline system. Industrial strainers usually consist of a main body, an internal screen basket, and a blow-off valve. By definition a strainer provides a means of mechanically removing solids from a flowing liquid.

Duplex Strainers

Duplex Strainers are designed for applications where flow cannot be shut down to service the strainer screen. Change over is accomplished by use of butterfly valves.They are very economical because they are fabricated to your specific requirements and with your choice of valves.This arrangement provides a bubble-tight shut off between basket chambers, essential for use in negative head pump suction systems.

Y Strainers

Y Strainer take their name from their configuration. are cast in sizes ¼" – 24" with Threaded, Socket Weld or Flanged End connections. Strainer are your most economical choice for large debris removal. They are most commonly used in pressurized lines, gas or liquid, but can also be used in suction or vacuum conditions. Y-Strainer has the advantage of being able to be installed in either a horizontal or vertical position. However, in both cases, the screening element or "leg" must be on the "downside" of the strainer body so that entrapped solids can be properly collected and held for disposal.

Conical Strainers / Temporary Strainers

DK engineers offers replacement screens and baskets and temporary strainers not only for our own products but for those of our competitors as well. Basket, Cone, Plate, Reverse Flow and many different engineering designs are available.

Ball valves

A ball valve is a flow control device which uses a hollow, perforated and pivoting ball to control fluid flowing through it. It is open when the ball's hole is in line with the flow inlet and closed when it is pivoted 90-degrees by the valve handle, blocking the flow. The handle lies flat in alignment with the flow when open, and is perpendicular to it when closed, making for easy visual confirmation of the valve's status.

The shut position 1/4 turn could be in either clockwise or counter-clockwise direction.

Ball valves are durable, performing well after many cycles, and reliable, closing securely even after long periods of disuse. These qualities make them an excellent choice for shutoff and control applications, where they are often preferred to gates and globe valves, but they lack the fine control of those alternatives, in throttling applications.

There are five general body styles of ball valves: single body, three-piece body, split body, top entry, and welded. The difference is based on how the pieces of the valve specially the casing that contains the ball itself are manufactured and assembled. The valve operation is the same in each case.

DK ENGINEERS is a leading ball valve manufacturer in Ahmedabad. Our production unit of ball valves mfg is equipped with advanced technologies and the latest manufacturing methods. We hold all the latest testing capabilities, and thus our customers receive high-quality products from our ball valves mfg in Ahmedabad. Quality products at a competitive price are the trademark of our high pressure valve mfg. Our production engineers are capable enough to produce custom valves to suit the business and application specifications of our customers. Therefore, we are the most demanded service of control valve manufacturers in India.

Special Features

- Free floating ball design provides seat wear compensation and longer life.

- Provide fire safe design as per APO 607 / API 6FA / BS 6755-II with single point contact seat design.

- Blow out proof and Anti blow out stem construction.

- Micro-finished ball provides a positive seal.

- Straight through flow path for minimum pressure drop.

- Bi-directional flow.

- 90° (Quarter-turn) actuation.

- Wide selection of seat materials.

- Extended stem/extended bonnet design as per customer’s specific pipe line usage.

- Antistatic devices ensure electrical continuity between Body, ball & stem.

- Triple stem seal with accurate stem.

- Handle indicates flow direction.

- Valves meet the requirements of fugitive emission levels shell category B as per MESC SPE 77/312.

- ISO 5211 top mounting pad for simplified gear / actuator in 150#, 300# & 600# as optional in only flanged end design.

- Variety of end connections.

Flow Meters manufacturer in India

A flow meter is a device that measures how much liquid or gas moves through a pipeline in a given period of time. By measuring flow rates, flow meters provide crucial visibility into what's flowing where, within pipes, drainage systems, and other types of infrastructure.

They are based on the principle of Faraday's Law of Electromagnetic Induction, according to which liquid generates voltage when it flows through a magnetic field. The more rapid the fluid flow, the more the voltage generated. Summary. Flow meters are mainly tw0 types mechanical and differential pressure type. Most of the flow meters measure volume flow rate.

DK ENGINEERSdesigned for measuring and indicating flow and total volume of conductive liquids. As there are no moving parts in the flow profile the device can be used to measure extremely dirty liquids containing solids. The flow meter is for use with conductive liquids only. Range of Applications. The flow meter has been designed for use in all process industries including chemical, water and waste water. Features. The inductive flow meter is a highly accurate and stable device. The construction of the flow meter uses components with a long-term time and temperature stability.

We have a wide range of Field/Panel mounted type of meters, in which calibration factor is programmable.

These meters are highly accurate, having optimized structure, highly reliable, more competitive than the similar type flow meter. We think, these flow meters are an ideal flow meter used in all kinds of most popularity measuring system. Our R&D department is continuously working to make these meters user facility.

Types Of Flow Meters

- Coriolis.

- DP Meters.

- Magnetic Meters.

- Multiphase Meters.

- Ultrasonic Meters.

- Vortex Meters.

Oil filter supplier in india

An oil filter is a mechanical device that removes contaminant, dirt, and unburned fuel from circulating. The component allows just the circulation of fresh oil into the engine and it keeps the dirt. This is why the oil filter needs to be treated or change within some period of time

Air Filtering System:

We are considered as a real part of the most the recognized associations occupied with manufacturing and supplying Air Filtering System. The channels we are putting forth are produced as per worldwide norms by utilizing quality-endorsed material sourced from the trusted merchants of the business sector.

Features:- Easy installation, Durability, Low maintenance.

Hydraulic Filter Element:

Avail from us, the superior quality Hydraulic Filter Element, which acts as a replaceable element for various national brands for disposable and cleanable type, or wrapped and pleated type. In order to meet various requirements of clients, we provide these products in different specifications laid by them. Further, these Hydraulic Filter Elements are offered at rock bottom prices in the market.

Features:- Highly efficient, High performance, Easy to use.

Industrial Electric Air Filter:

We are providing our esteemed clients with an excellent quality gamut of Industrial Electric Air Filter. At our well advanced manufacturing unit, our offered electric air filter is manufactured in line with set industry norms by our talented professionals. In addition, our provided electric air filter is made available in huge range of specifications and that can be customized too as per the clients' necessities.

Features:- Simple to install, Sturdiness, Rust proof

Industrial Moulded Air Filter:

With rich industry experience and knowledge, we are offering quality approved range of Industrial Moulded Air Filter that is used in variety of applications. Our highly skilled professionals manufacture this air filter by making use of the high grade material and advanced machines. Offered air filter is made obtainable in numerous sizes and other related specifications to cater the varied requirement of our customers. Besides, client can avail this air filter from us at affordable prices.

Features:- Easy installation, Strong design, High strength.